When designing a Customized corrugated color box gift box, it is crucial to ensure that its structure can provide stability and protection.

1. Choice of corrugated cardboard

Corrugated cardboard is the main material of customized gift boxes. Its selection plays a decisive role in the stability and protection of the overall structure. Usually, corrugated cardboard is divided into different "fluting types", such as A, B, C, E, etc., each fluting type has its own unique compressive strength and stiffness. Designers will choose the appropriate fluting type according to the purpose, size and expected load of the gift box.

2. Structural design

a. Shell design

The shape and size of the shell are the first step in the design. According to the shape, size and quantity of the gifts, the designer will determine the outer contour of the gift box. Generally speaking, the shape of the shell may be a cuboid, cube, cylinder or other special shape to maximize the fit of the internal gifts. At the same time, the designer will also consider the stacking and transportation convenience of the gift box to ensure that the size is reasonable. Corrugated cardboard (corrugated cardboard) is the main material of the shell, and its selection directly determines the strength and stability of the gift box. Designers will choose the appropriate flute type (such as A, B, C, E, etc.) and cardboard thickness according to the weight, volume and expected transportation conditions of the gift. At the same time, the configuration of the corrugated cardboard is also key, usually including single-sided corrugation, double-sided corrugation or reinforced corrugation, etc., to ensure that the shell has sufficient load-bearing capacity and compressive strength.

b. Liner design

The liner is the structure inside the gift box, which is used to fix and support the gift. The design of the liner needs to be customized according to the shape and size of the gift. Through reasonable liner design, it can ensure that the gift remains stable during transportation and storage, and avoids sliding or collision.

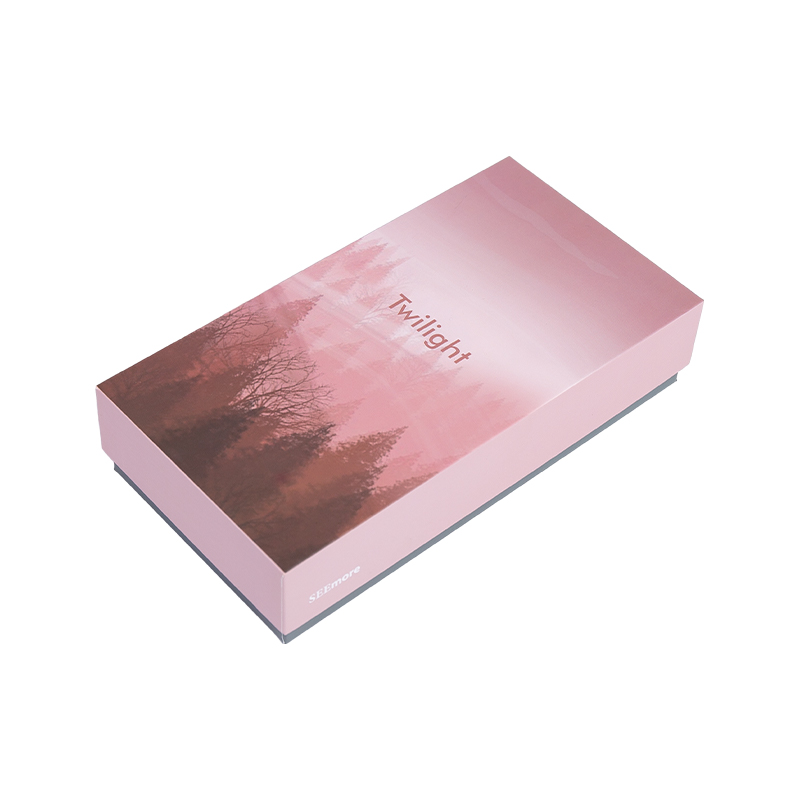

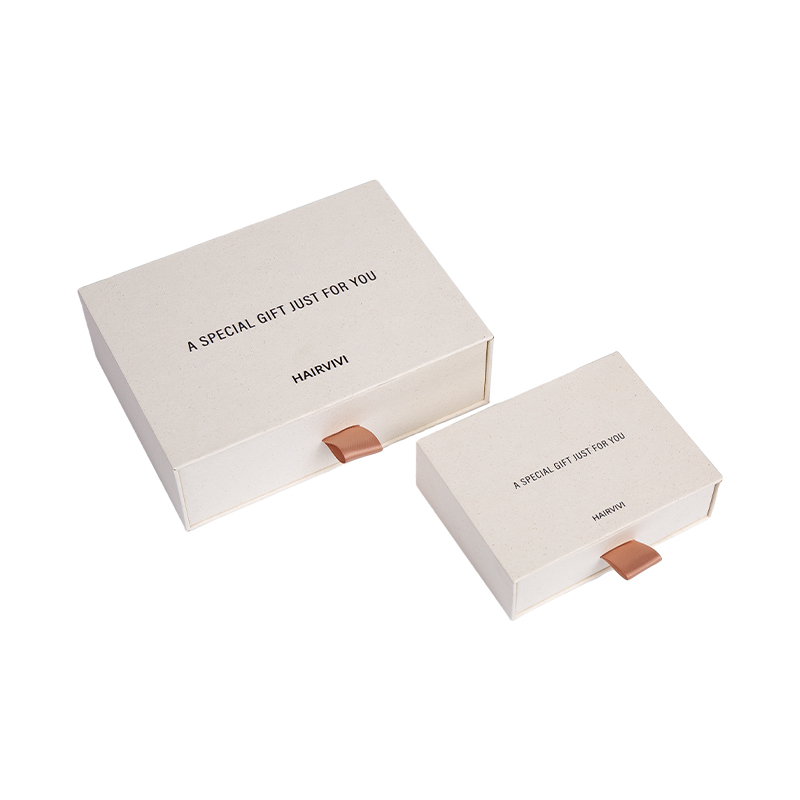

c. Lid design

The lid is an important part of the gift box. It not only provides additional protection, but also increases the beauty of the gift box. The design of the lid needs to consider its opening method, sealing and durability. Common lid types include flip-top, drawer-type and sliding-type. Through reasonable design, it can be ensured that the lid fits tightly with the shell to provide good sealing and protection.

d. Handle and handle design

If the gift box needs to be easy to carry, then the design of the handle and handle is particularly important. The position, shape and material of the handles and handles need to be carefully designed to ensure that they can bear the weight of the gift box and provide a comfortable grip.

3. Detail processing

a. Edge processing

The edges of the gift box are easily damaged, so special treatment is required to enhance its strength and durability. Common treatment methods include folding, indentation and gluing. These treatments can ensure smooth and flat edges and reduce the risk of damage during transportation and storage.

b. Bonding and fixing

During the production process of gift boxes, glue or other adhesives are needed to bond different parts together. The selection and use of adhesives need to be carefully considered to ensure that the bonding is strong and not easy to fall off. In addition, appropriate fixings (such as nails, screws, etc.) need to be used to enhance the stability of the structure.

4. Testing and optimization

After completing the preliminary design, the gift box needs to be subjected to a series of tests to ensure its stability and protection. These tests include compression tests, drop tests, vibration tests, etc. Through testing, problems in the design can be discovered and optimized and improved.

The structural design of the customized corrugated color box gift box is a process that comprehensively considers material selection, structural design, detail processing and test optimization. Through careful design and production, we can ensure that the gift box has excellent stability and protection to provide the best packaging solution for gifts.

中文简体

中文简体

English

English