Halloween shaped gift box

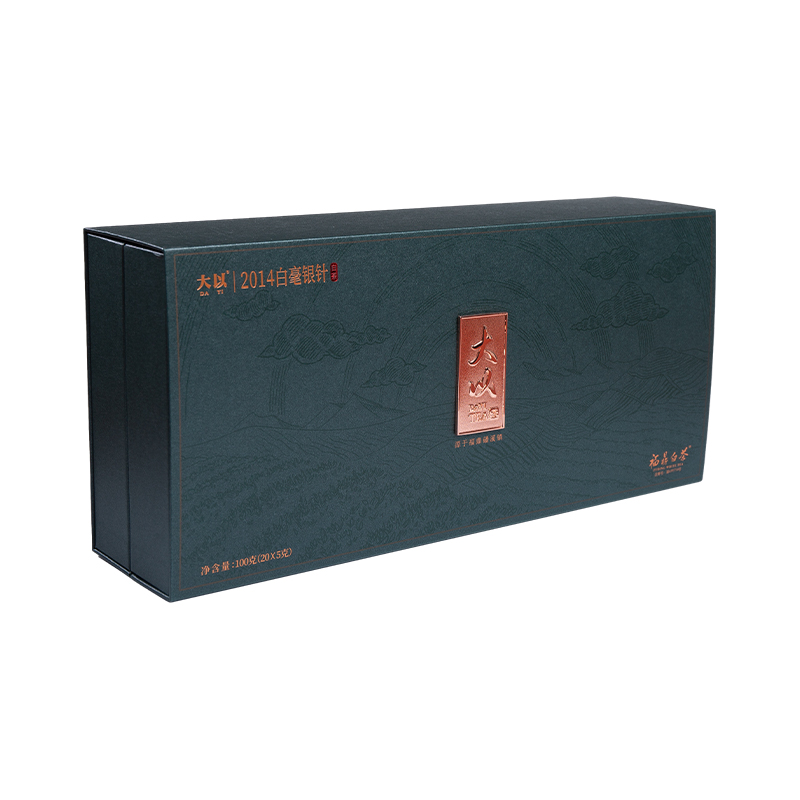

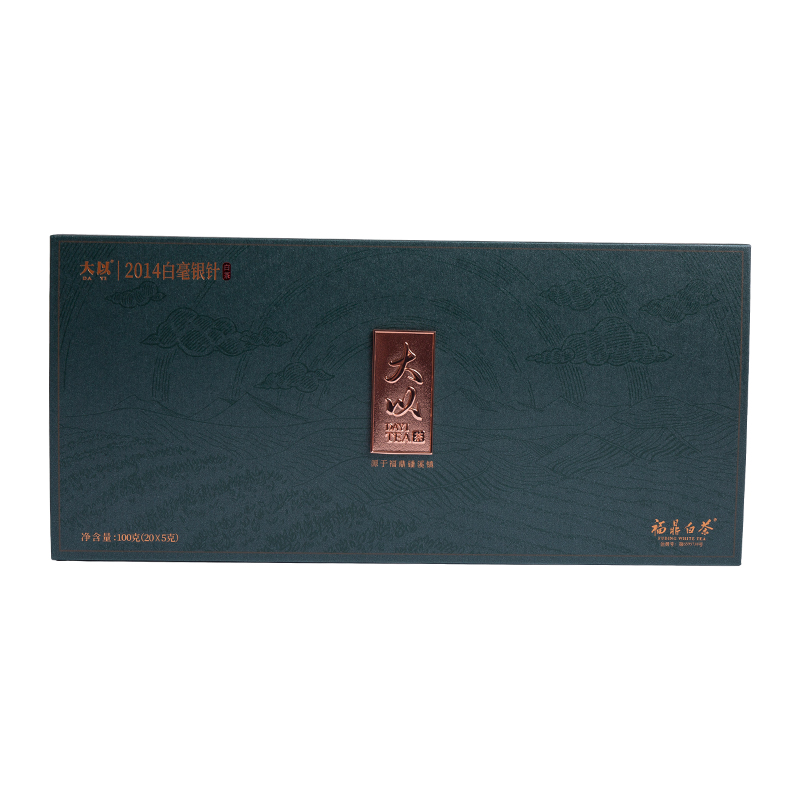

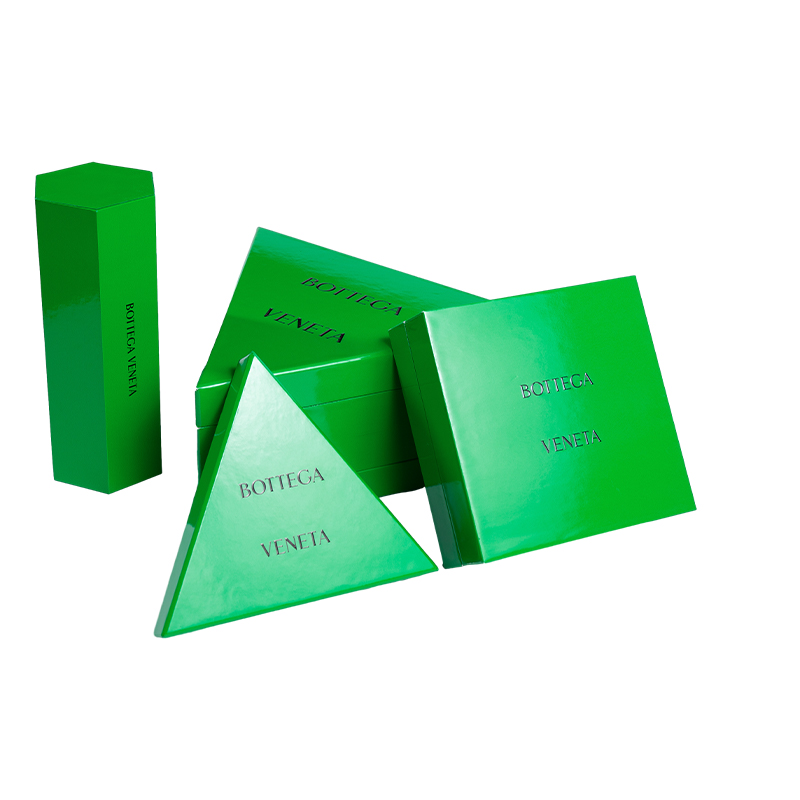

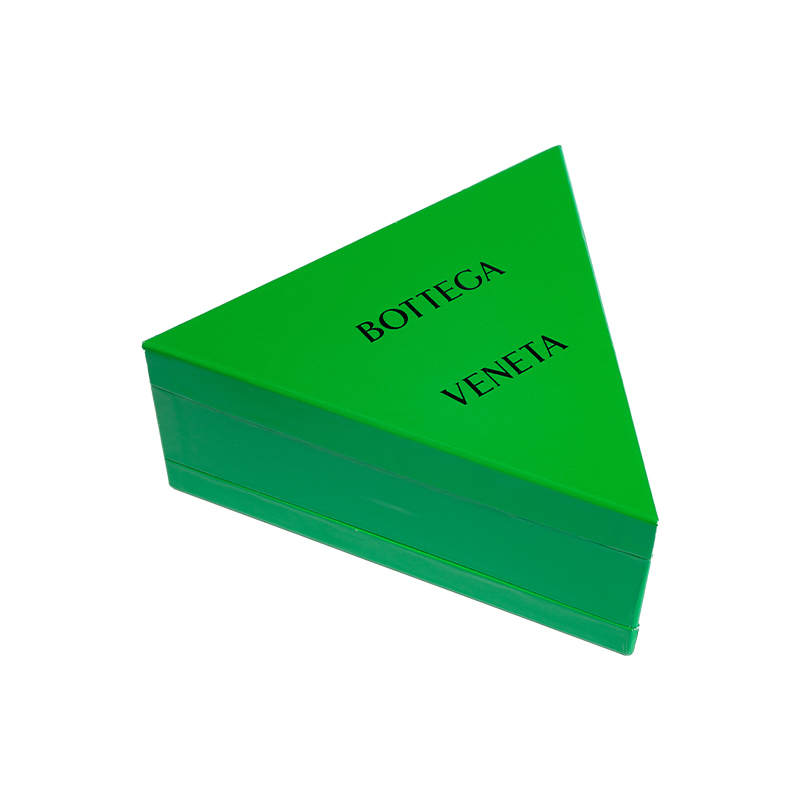

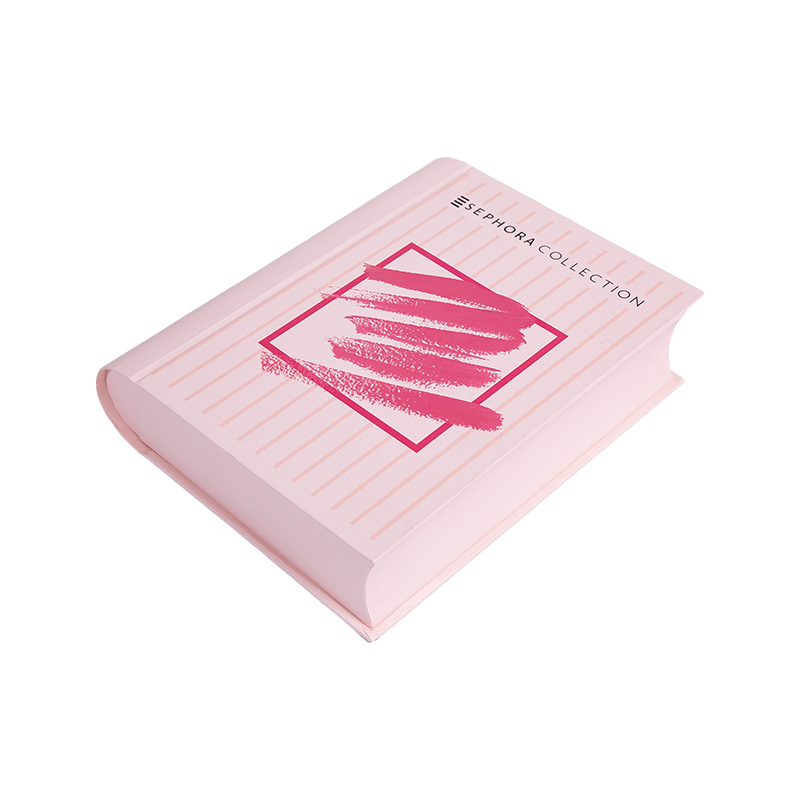

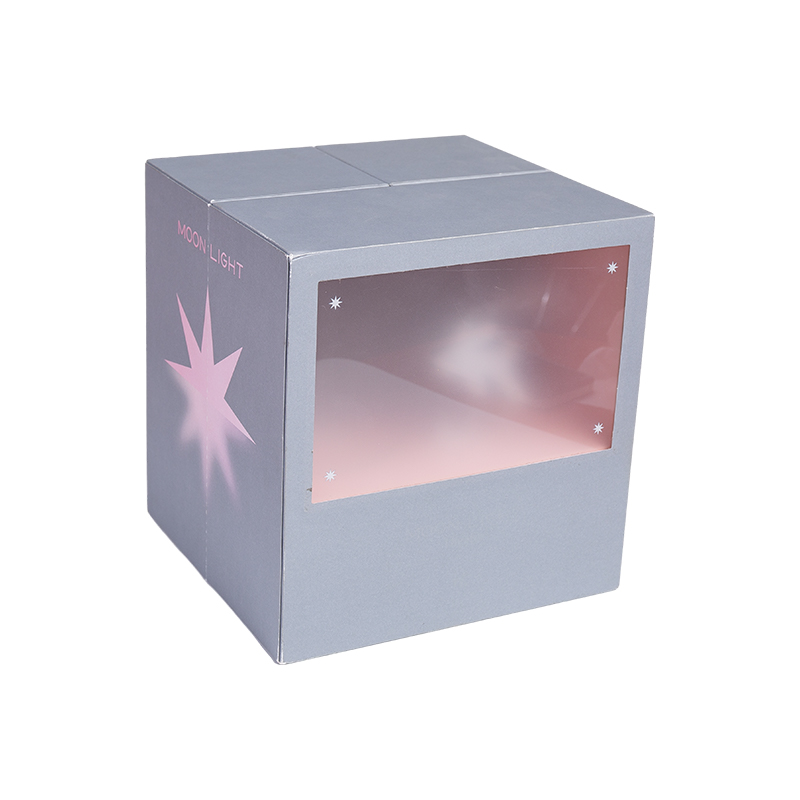

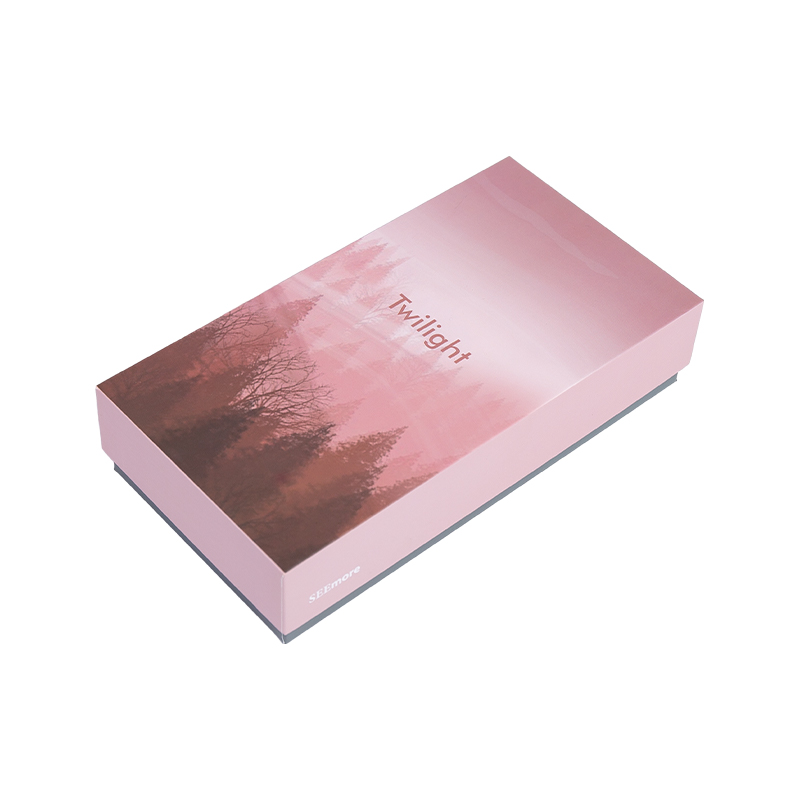

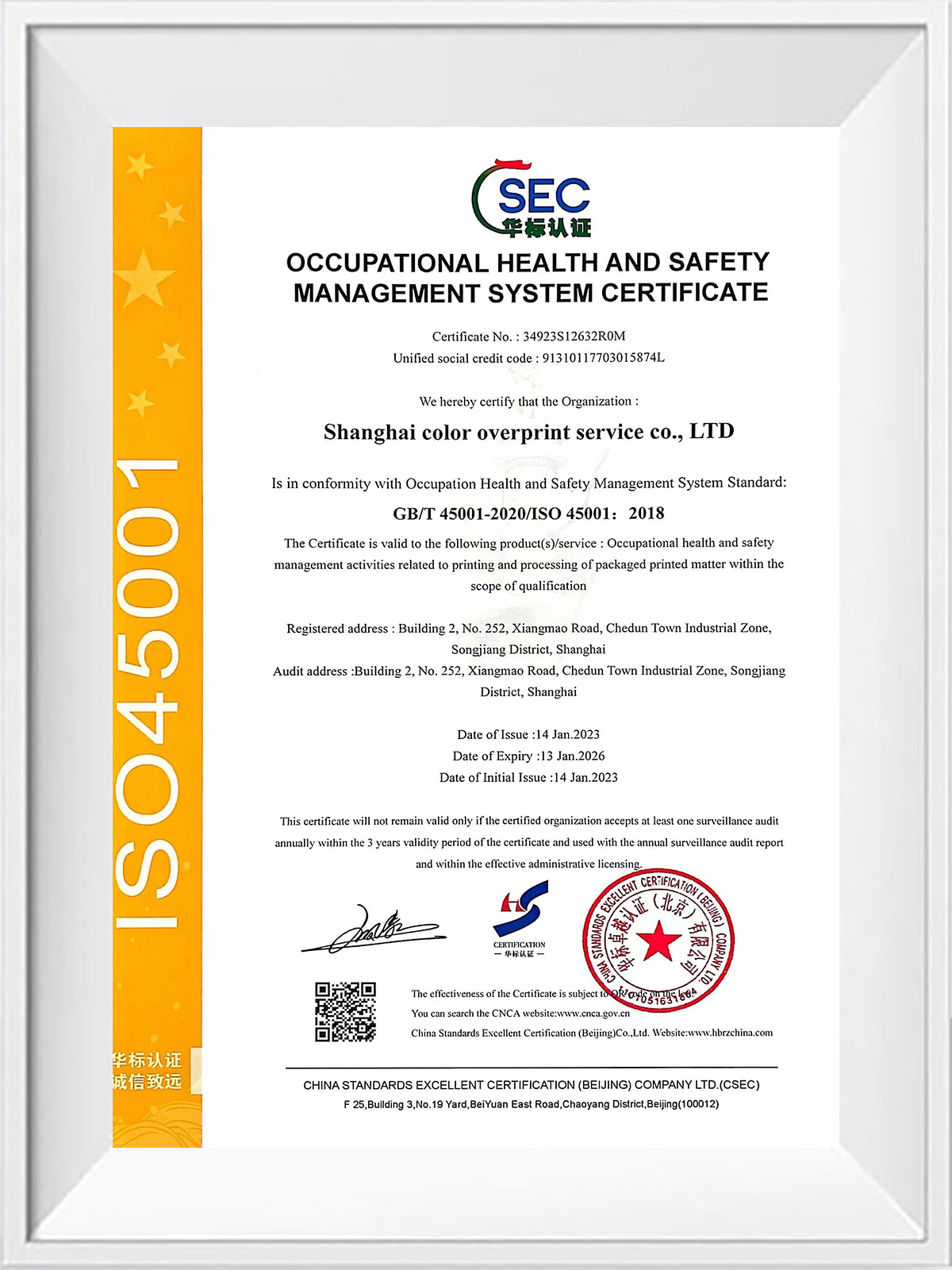

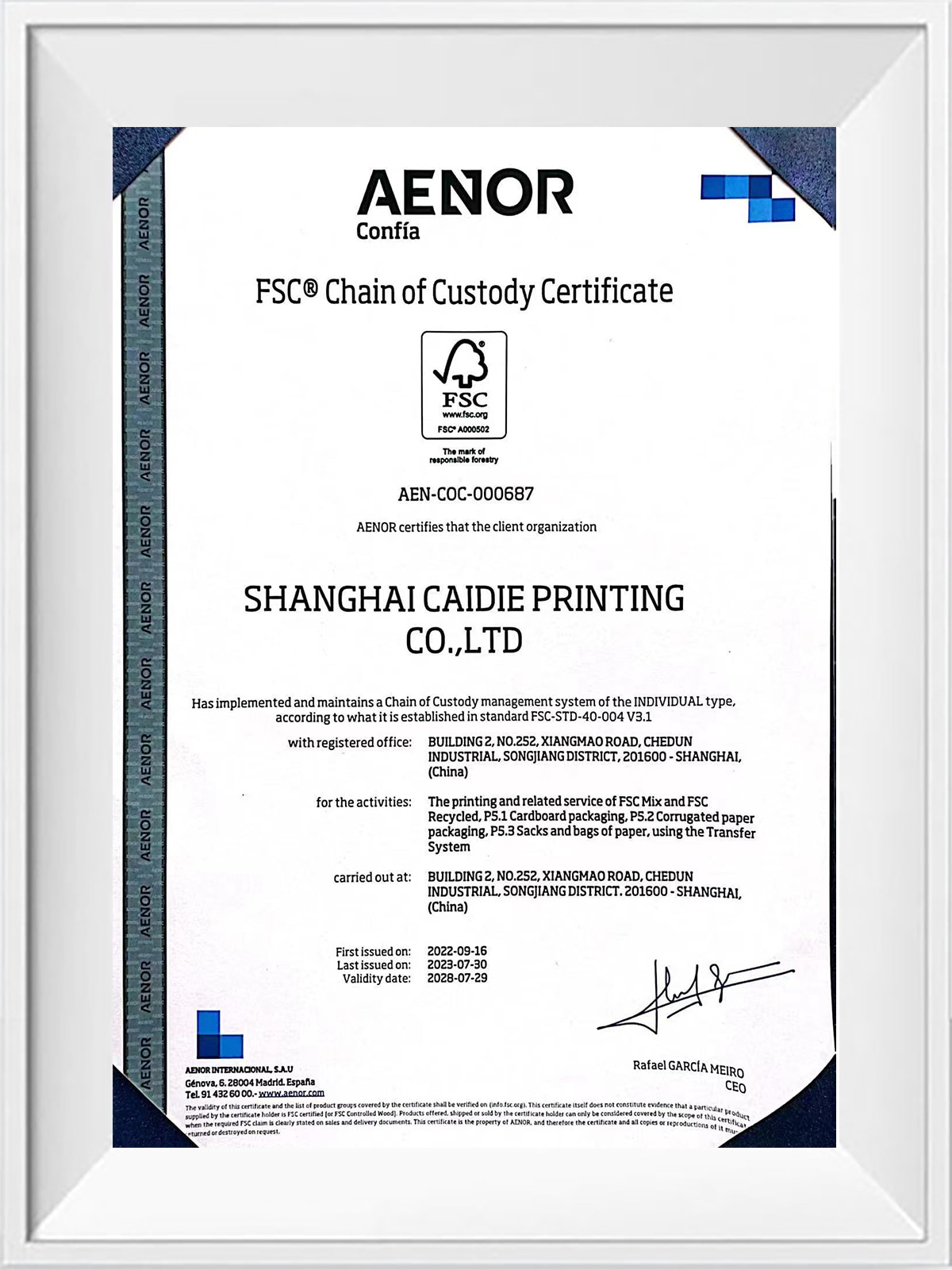

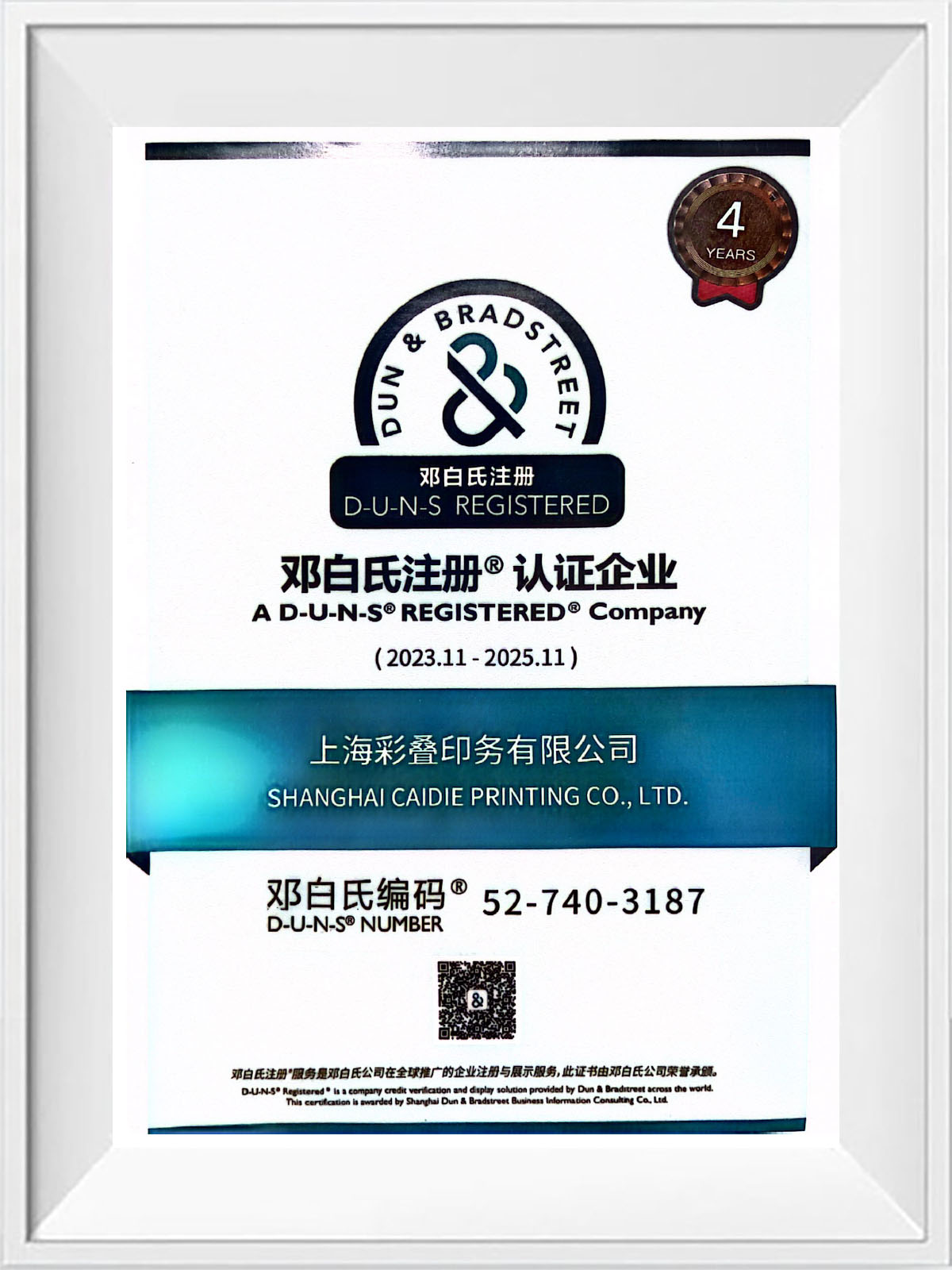

As a China Wholesale Printed Halloween shaped gift box Manufacturers and Custom Halloween shaped gift box Factory , employing advanced printing technologies and eco-friendly materials, we are committed to delivering exceptional packaging services for food, beverage, consumer goods, electronics, and various other industries.

-

Expansion of Light-Emitting Gift Box/Card Business

1: NFC coil photoelectric label unit price (gross level, without NFC chip, basic flashing only); 2: NFC coil photoelectric label unit price (gross level, with NFC chip, customizable flashing); 3: NFC ...

READ MORE -

Crafting the Perfect Christmas Eve: The Gift Box That Holds More Than Presents

As the holiday season approaches, the market signals a familiar shift: consumers become curators of meaning, retailers transition into storytellers, and packaging evolves from simple containment to em...

READ MORE -

How Can a Sturdy Christmas Gift Box Elevate Your Christmas Eve Surprises?

Christmas Eve remains one of the emotionally anticipated nights of the year—an evening shaped by warm lights, shared memories, thoughtful gifts, and symbolic rituals. While the heart of the celebratio...

READ MORE

How can companies ensure that Halloween-shaped gift boxes maintain high quality standards during design and production to meet customer needs for durability, aesthetics, and safety?

At ColorFold Printing and Packaging Services Co., Ltd., we are well aware of the importance of high quality standards for Halloween-shaped gift boxes, which is directly related to the market image, user experience, and safety of our customers' products. In order to ensure that each gift box can meet high standards of durability, aesthetics, and safety, we have adopted a series of carefully designed processes and measures.

1. Preliminary demand analysis and design optimization

We work closely with customers to gain an in-depth understanding of their brand concepts, target markets, and specific product features. Through detailed demand analysis, our design team is able to create a design that is both in line with the Halloween atmosphere and reflects the characteristics of the customer's brand. During the design process, we pay attention to detail processing to ensure that the pattern, color, and shape are perfectly integrated to enhance the aesthetics of the gift box. At the same time, we will also consider the rationality of the structure and optimize the design through simulation tests to improve the durability of the gift box.

2. Select high-quality materials

The selection of materials is the key to ensuring the quality of gift boxes. We insist on using strictly screened environmentally friendly materials, such as recyclable cardboard, biodegradable plastics, etc. These materials not only meet environmental protection requirements, but also have good physical properties, such as compression resistance, wear resistance, waterproofness, etc., to ensure the durability of gift boxes. At the same time, we will conduct quality inspections on each batch of materials to ensure that they meet the established standards.

3. Advanced printing technology

ColorFold uses advanced printing technologies, such as digital printing, UV printing, etc., which can accurately restore the color and details of the design draft, making the pattern of the gift box more vivid and lifelike, and enhancing the aesthetics. In addition, we also pay attention to quality control during the printing process, and ensure that the color of each batch of products is consistent and without deviation through professional color management systems and printing equipment calibration.

4. Fine manufacturing process

During the production process, we use a combination of automated production lines and manual finishing to ensure the production accuracy of gift boxes. Automated production lines improve production efficiency and consistency, while manual finishing focuses on detail processing, such as edge grinding, folding alignment, etc., to make gift boxes more refined. In addition, we also implement a strict quality inspection process, including first-piece inspection, process inspection, and finished product inspection, to ensure that every gift box meets quality requirements.

5. Safety test

Safety is an aspect of gift boxes that cannot be ignored. We will conduct a series of safety tests on the finished products, such as heavy metal content detection and formaldehyde emission detection, to ensure that the gift boxes will not cause harm to human health. At the same time, we will also check the performance indicators of the gift boxes, such as sealing and load-bearing capacity, to ensure that they can protect the product safety and integrity during use.

6. Continuous improvement and customer feedback

We attach importance to customer feedback, and continuously optimize the design and production process by collecting and analyzing customer evaluations of gift boxes. We have established a complete after-sales service system to respond to customer needs in a timely manner and solve possible problems. In addition, we also regularly communicate with suppliers, industry associations, etc. to understand industry dynamics and technological development trends in order to continuously improve the quality of products and services.

ColorFold ensures that Halloween-shaped gift boxes maintain high quality standards during the design and production process through early demand analysis and design optimization, selection of high-quality materials, use of advanced printing technology, fine manufacturing processes, implementation of safety testing, and continuous improvement and customer feedback to meet customer needs for durability, aesthetics and safety.

中文简体

中文简体

English

English